Overview

Wind turbines harness the forces of nature to give us clean, renewable energy. In the process, all elements of the tower and its foundation are exposed to the wind causing the entire structure to move.

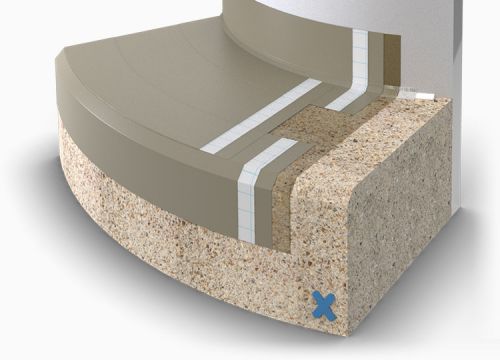

This movement can result in the formation of cracks in the foundation, allowing moisture to penetrate the structure and potentially leading to longer term damage. Triflex Towersafe is a specially developed solution designed to waterproof the tower, foundation, joints, flanges, nacelles and for specific details including blade root. Other solutions include coatings and filling compounds for both new and for refurbishment. The fully reinforced system can be installed quickly to minimise downtime, and can easily withstand the unique demands of this tough environment.

Triflex Towersafe in action

System highlights

Universal application

The specially formulated Triflex Towersafe solution is designed to waterproof all areas of the wind turbine. From the tower and base to the nacelle, Triflex Towersafe can be used to provide long lasting and sustainable protection. Even areas under soil can be reliably waterproofed as the cured membrane is FLL certified as root and rhizome resistant as standard.

Cold applied, fast curing with rapid installation

Rapid curing and easy to install, Triflex Towersafe allows works to be completed in less than a day resulting in shorter downtimes. Installation can be carried out around all year round and the system still cures quickly at temperatures down to -5°C and is rainproof in just 30 minutes. There is also no risk from hot works during installation as all our materials are applied in a totally cold liquid form, curing to create a solution that lasts.

Single process application

Reduce installation costs associated with multi-coat solvent based systems, save significant time on site and eliminate risks from inter-layer adhesion with our simple, single process waterproofing application. Triflex Towersafe has a thixotropic formulation as standard, allowing it to be used on vertical or even inverted surfaces.

Fully reinforced technology

The special polyester fleece reinforcement used in Triflex Towersafe is designed to work with the elastomeric Triflex Towersafe resin to accommodate high levels of movement and cracking within the structure and between different substrates. Proven fully reinforced waterproofing technology that stands the test of time.

Tried and tested

Triflex Towersafe offers a complete wind turbine waterproofing solution that will last for years to come. The system is not only certified and tested to the highest UK and European standards including BBA and ETAS 005, it has also been successfully installed in projects across the globe.

Colours and finishes

Create a design to meet your aesthetic or safety requirements with a wide range of colours and two optional finishes - refer to Triflex Towersafe colour card.

Application areas

- Wind turbine foundation

- Wind turbine joints and flanges

- Nacelles

- Detail applications

Compatible substrates

- Cementitious materials (concrete, grout)

- Metals and coated metals

- Plastics and coatings (e.g. polyurethane, polyurea, polymethyl methacrylate, acrylic, GRP)

System variants

Require an on-site survey or quote?

All installations are carried out by our network of Triflex Authorised Contracting Partners. If you have a project we can provide a free no obligation on-site survey and can put you in touch with local Triflex contractors in your area that will be able to provide you with a quote.

To organise your free on-site survey you can either complete our project enquiry form or contact your local Business Development Manager, who will be more than happy to discuss your requirements.

Triflex Authorised Contracting Partners can place orders by calling 01785 819119 or emailing orders@triflex.co.uk.

Approvals

Fully certified to the highest UK and European standards and classifications, including:

BBA certified

- Durability: Under normal service conditions the system will provide a durable roof waterproofing with a service life in excess of 25 years

ETAG 005 certified

- Highest classification in all criteria including W3 – 25 year durability

UKTA certified

Fire performance

- BS 476-3 (EXT.F.AA)

- EN 13501-5: Class BROOF (t1) / (t2) / (t3) / (t4)

- EN 13501-1: Class E

Root and rhizome resistant

- FLL Certified: Root and rhizome resistant

Manufacturer certification

- ISO 9001: Quality Management

- ISO 14001: Environmental Management

- ISO 50001: Energy Management