The challenge

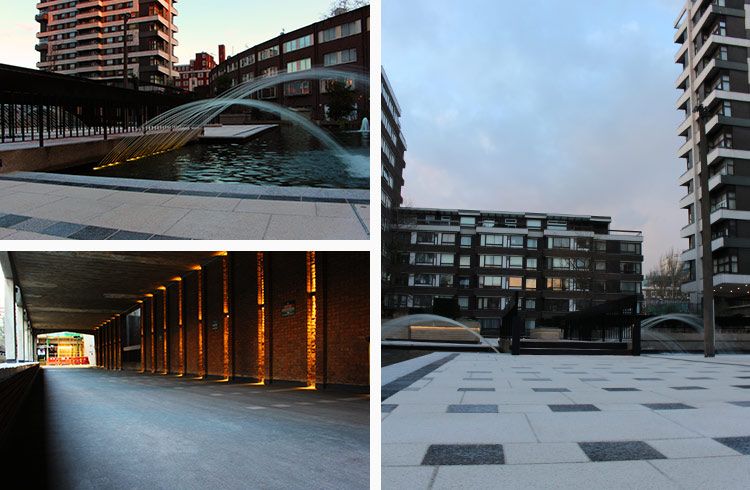

The Water Gardens are a set of three luxury apartment blocks located near the Royal Hyde Park in North London. Constructed in the early 1960's using a striking patterned concrete finish and modernist design, these apartment blocks contain a unique, attractive and extensive garden area with ponds and planters. Today the building is renowned for its luxury accommodation and prime location.

In January 2017, Triflex completed a project specification proposal for several areas within The Water Gardens. This was a complicated and in-depth project and utilised a variety of Triflex’s roof, walkway and car park systems.

The project required the waterproofing of apartment roofs, ponds containing valuable Koi Carp fish; concrete protection for planters with trees and aquatic plants; a buried reinforced waterproofing system for the podium decks and walkways; waterproofing and surfacing to a service road which runs from the access gate on the southern boundary of the site.

In total the project covered an area of 4,000m², all situated directly above a basement residential parking and storage area. Accordingly, it was important that all works had a minimal effect on the residents, and the Tenants Association were to be kept informed throughout.

Following the water being drained from the ponds, the Triflex Technical Team attended site to conduct extensive testing. The structure was found to be a reinforced concrete slab, with an additional concrete slab separated by bituminous filled movement joints to allow independent movement within the pond areas. Although these joints would be buried by the Triflex system they would require overbanding to control the risk of cracking to the completed system caused by continual movement within the structure.

Testing was conducted to determine the condition of the surface of the concrete slab, which identified poor cohesive strength within the concrete surface in the pond areas. A visual survey showed moisture running through the structure from above. Additional cracking was evident in places, especially along the lines of the day joints formed between the original pours of the slab during construction. It was evident that attempted repair works had been carried out over several years, but these too had failed and would require treatment.

An essential part of the challenge was managing the risk of tonnes of water within the ponds, and therefore providing a reliable and robust waterproofing solution was key.

Finally, the existing service road also required attention. The road runs beneath a concrete podium and had concrete kerbs, pavers and stone setts installed over the existing asphalt / macadam build-up. The road surfacing itself was in poor condition and showed evidence of numerous unsuccessful repairs which would require attention.

Bernice Maher, Associate Director from Colliers International had previously worked with Triflex and they were keen to partner again. This was due to the overall complexity of the project and her previous experiences with Triflex systems and the level of service provided by the Triflex Technical Team to help overcome challenges.

The solution

Triflex were able to specify a solution to each of these areas utilising PMMA resins. PMMA or polymethylmethacrylate is the technology behind the vast majority of Triflex systems. Unlike other resin technologies such as polyurethane (PU), epoxy (EP) and polyurea (PUA), PMMA is rapid curing and can be installed at low temperatures. It is hydrolysis resistant, so it will not be broken down by water over time, and as such is ideally suited to the ponds and fully submerged planting areas. Not only is PMMA highly waterproof, it is also isocyanate and solvent free, reducing the risk of harm to residents, aquatic life and installers.

With the surface of the concrete within the ponds being in poor condition, Triflex Cryl Primer 280 White was specified to improve its cohesive strength. This extremely low viscosity primer works by percolating into the surface of the concrete and binding together the fine aggregates, improving overall cohesive strength.

Prior to installing any Triflex waterproofing systems to the decks and walls of the ponds, all cracks and joints were overbanded using the fully reinforced Triflex ProDetail. Triflex ProDetail was utilised to ensure that movement and cracking within the structure, and between substrates could be accommodated.

Following the completion of the priming and overbanding, two applications of Triflex ProDetail were installed to waterproof the planters. The bases of the ponds were waterproofed with two layers of Triflex ProTect.

The fully reinforced Triflex ProDetail and ProTect systems are FLL certified root and rhizome resistant, and would provide protection to the concrete planters from the plant life contained within. Both systems have been extensively used to provide waterproofing membranes for green roofs, including those, as in this case, classified as extensive. This meant suitable drainage and filtration membranes were required within the planters and water was diverted to drainage outlets which in some cases fed the water directly back into the ponds.

A buried waterproofing solution was required for the podium decks and walkways around the ponds. Colliers International had specified large white pavers for the overburden. Triflex ProTerra Buried with Heavy duty finish (BBS HD) was specified. It can be used in conjunction with a wide range of both loose laid and fully bonded overlay solutions and met the needs of the project.

Finally, the last area to receive attention was the service road. The Triflex ProPark system was specified to directly overlay the existing asphalt. Triflex ProPark is the industry leading waterproofing and surfacing solution for overlaying asphalt car parks. BBA and EN 1504-2 certified, it is exceptionally fast curing, even at low temperatures and allowed the road to reopen quickly.

During the surfacing work to the service road, it was questioned whether the nature of traffic might change to heavier delivery vehicles within the next few years. If this was to be the case, Triflex ProPark could easily be adapted to the Triflex ProPark Service Deck (AWS) system variant, which features a sacrificial wearing layer above the waterproofing membrane. This additional layer is designed solely to deal with the high shear forces and impacts imposed by HGV’s, and to protect the underlying waterproofing.

After the ponds were filled, the plants bedded in the planters and the paving installed on the podium, The Water Gardens were re-opened to the residents and fish in November 2018. The entire project was completed over the course of 18 months.