Efficient working and effective results with PMMA resins and mortars

Triflex offers optimally matched cold applied repair and reinstatement resins and mortars for every infrastructure challenge. Solutions are easy to mix and apply, quickly resilient (even at very low temperatures), durable, wear-resistant and are not broken down by water. When it comes to the maintenance of infrastructure, Triflex is your long term partner.

Your project is our project. As a manufacturer and direct seller rather than distributor - Triflex is closer to the products, the project and the end user. Our experienced technical team and field application engineers support you in selecting the right products and installing effectively.

Compatible and versatile solutions

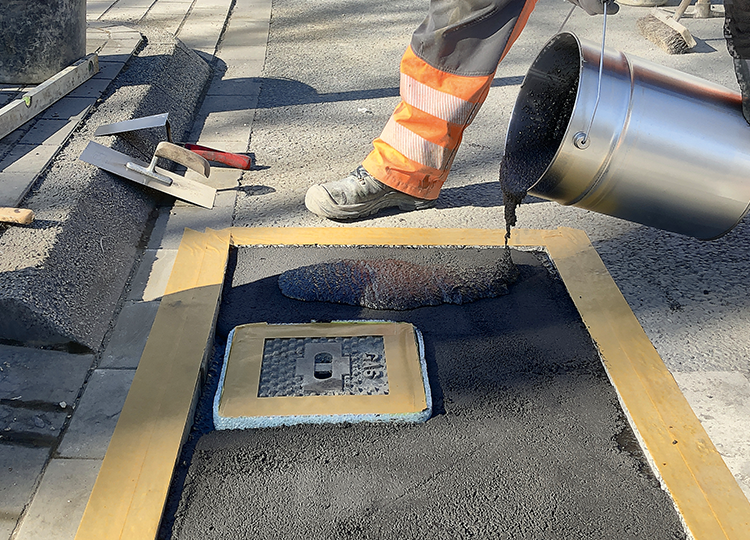

With Triflex PMMA specialist resins and mortars, you can, not only repair potholes, around manholes, breakouts and dayjoint cracks, but also cover fatigue or reflection cracks and rutting. You can even replace the surface of damaged asphalt with a thin layer surfacing. Slip resistance can be tailored with a choice of embedded aggregates.

Triflex offers optimally matched cold applied repair and reinstatement resins and mortars for every infrastructure challenge. Solutions are easy to mix and apply, quickly resilient (even at very low temperatures), durable, wear-resistant and are not broken down by water.

Benefits of PMMA resin repair materials

PMMA resin repair materials are substitutes for holt and cold asphalts and offer decisive advantages: They can be processed at temperatures down to 0°C and are exceptionally fast curing, with less time taken to carry out the project. With high mechanical and physical properties, they are highly resistant to traffic, are compatible with bituminous, cementitious and metallic substrates and are water resistant. Long term repairs can now be realised with a low risk, cold applied solution even in the colder months, and for emergency repairs, without the requirement to open an asphalt plant just for the repair of that incident. The ease in which they can be applied means that less personnel are needed to complete the works. This in turn leads to less equipment being used, cutting down on costs.

Disruption is minimised as the material can typically be driven over after as little as 45 minutes. Triflex products are perfect for specialist companies and non-specialist contractors alike being simple to mix and apply using basic tools. With its range of specially developed products, Triflex offers an alternative to the maintenance of our road and highway infrastructure, allowing them to be maintained in a fair and responsible way.

The use of PMMA resins and mortars is not only economical and sustainable, but makes an active contribution to road safety. The term PMMA may not be familiar, but the technology is far from new to the highways sector. Superior PMMA road markings are widely used throughout Europe, where demands for high performance reflective markings are significantly higher as cats eyes are typically not used.

Reasons for using PMMA in infrastructure

Being totally cold applied and mixed on site, the technology offers huge advantages over traditional hot applied materials. Cookers, hot boxes, road rollers etc. are not required, significantly reducing mobilisation costs and reliance on logistics.

As the system can be applied in thinner layers, it may also mean less preparation and less material sent to landfill or recycling. The fast curing time means the repaired area can also be re-opened to traffic after only a short time. For most construction chemicals, drying, curing and hardening times are slow and will be significantly extended in cold temperatures, making their use on roads and highways impractical.

With PMMA, formulations can be designed to work at temperatures as low as -20°C with no extension of cure times (a Triflex PMMA manhole installation mortar for Scandinavia is designed to do just this), whilst also being able to deal with atmospheric humidity of up to 95%. All of these properties make PMMA an ideal solution to comply with challenging schedules of repairing roads and highways infrastructure with the added advantage of minimising traffic management costs.

Infrastructure Whitepaper

The volume of traffic on UK roads has been constantly increasing. The reasons for this development lie in the increasing mobility of society, economic growth and our ever-increasing reliance on road transport for the products we buy and consume.

The road network is therefore of outstanding importance to the people of the UK for mobility, personal consumption and for business. More traffic on the roads means more stress and the need to invest more in maintaining them. Given a road network which covers a total of 247,500 miles, maintenance and refurbishment poses an enormous challenge particularly given the demands of other sectors for public finances.