Vehicles rolling along car park surfaces generate an electrostatic charge, in the majority of cases this electrostatic charge will dissipate to ground through the tyres. However in certain cases, where the car park surface has high electrical resistance, such as traditional asphalt build-ups, the charge can remain for a period of time. If a driver then touches an earthed metal object such as a ticket machine, they can receive a static electric shock. Triflex DeckFloor Anti-Static is a specialist waterproofing and surfacing solution that eliminates this issue. The system combines unique conductive waterproofing resin technology with an earthed copper pad to effectively dissipate any electrostatic charge build-up. Used successfully in problem car parks across the UK, the solution improves user experience while still providing our industry leading waterproofing and surfacing protection.

Anti-skid

Tests carried out wet on new indicative samples in accordance with UKSRG Guidlines (2016):

With 1.0 - 3.0mm emery:

- PTV approx. 97 (Four S rubber / Slider 96)

- PTV approx. 86 (TRRL rubber / Slider 55)

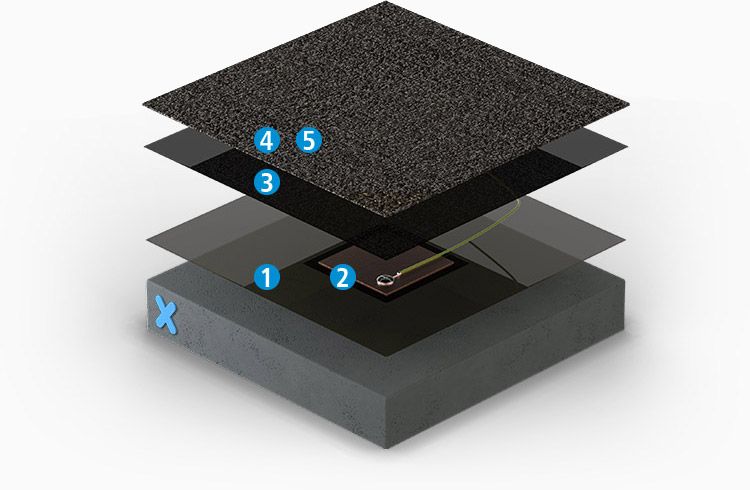

System build-up

Primer

Cryl Primer 222

Primer for asphalt, bitumen, timber and other substrates.

Overcoat / traffic: 45 minutes

Consumption: 0.40Kg/m²

Earthing

Copper Pad

Embedded into Triflex Cryl R 231 EX

Cryl R231 EX

Overcoat / traffic: 1 hour

Consumption: 0.30Kg/m² min.

Anti-static primer

Cryl R231 EX

Overcoat / traffic: 1 hour

Consumption: 0.30Kg/m² min.

Anti-static waterproof wearing layer

Triflex DeckFloor EX

Overcoat / traffic: 3 hours

Consumption: 3.00Kg/m²

Aggregate: Electro corundum: 4.00Kg/m²

Finish

Cryl Finish 208 EX

Foot traffic: 2 hours

Vehicle traffic: 3 hours

Consumption: 1.00Kg/m²